10 Ultimate Benefits of Magnetic Grippers Transforming Industry Efficiency

In the fast-paced landscape of modern manufacturing and logistics, the integration of advanced technologies is pivotal for enhancing productivity and efficiency. One such transformative tool is the Magnetic Gripper, which has been proven to revolutionize the handling of materials across various industries. According to a report by MarketsandMarkets, the global automation market is poised to reach $214 billion by 2026, with increased adoption of smart industrial tools like Magnetic Grippers playing a crucial role in this growth. These grippers not only streamline processes by enabling faster product handling but also reduce operational costs significantly. As industries continuously strive for optimization, understanding the myriad of benefits that Magnetic Grippers offer becomes essential for staying competitive. This article will delve into the ten ultimate advantages of Magnetic Grippers, outlining how they contribute to transforming industry efficiency.

Revolutionizing Material Handling: How Magnetic Grippers Enhance Safety

Magnetic grippers are rapidly transforming the landscape of material handling, providing an innovative solution that enhances safety and efficiency in various industrial processes. By utilizing powerful magnets, these tools securely hold and transport ferrous materials without the risk of damage. This not only reduces the likelihood of workplace accidents but also decreases material loss, ensuring that operations run smoothly. As industries face increasing demands for productivity, the integration of magnetic grippers is becoming essential in maintaining a safe work environment while maximizing throughput.

When implementing magnetic grippers in your workflow, consider these tips for optimal usage: first, ensure that the gripper is properly calibrated to match the weight and size of the materials being handled. This will prevent slippage and guarantee a secure grip. Second, conduct regular maintenance checks to keep the magnetic components functioning at their best. Lastly, provide training sessions for operators to familiarize them with the equipment, highlighting the importance of safety protocols when working with heavy loads.

The advancement of magnetic grippers also emphasizes the need for businesses to adapt to new technologies. Embracing these tools not only fosters a culture of safety but also encourages innovation in material handling processes, leading to a more efficient and effective workplace.

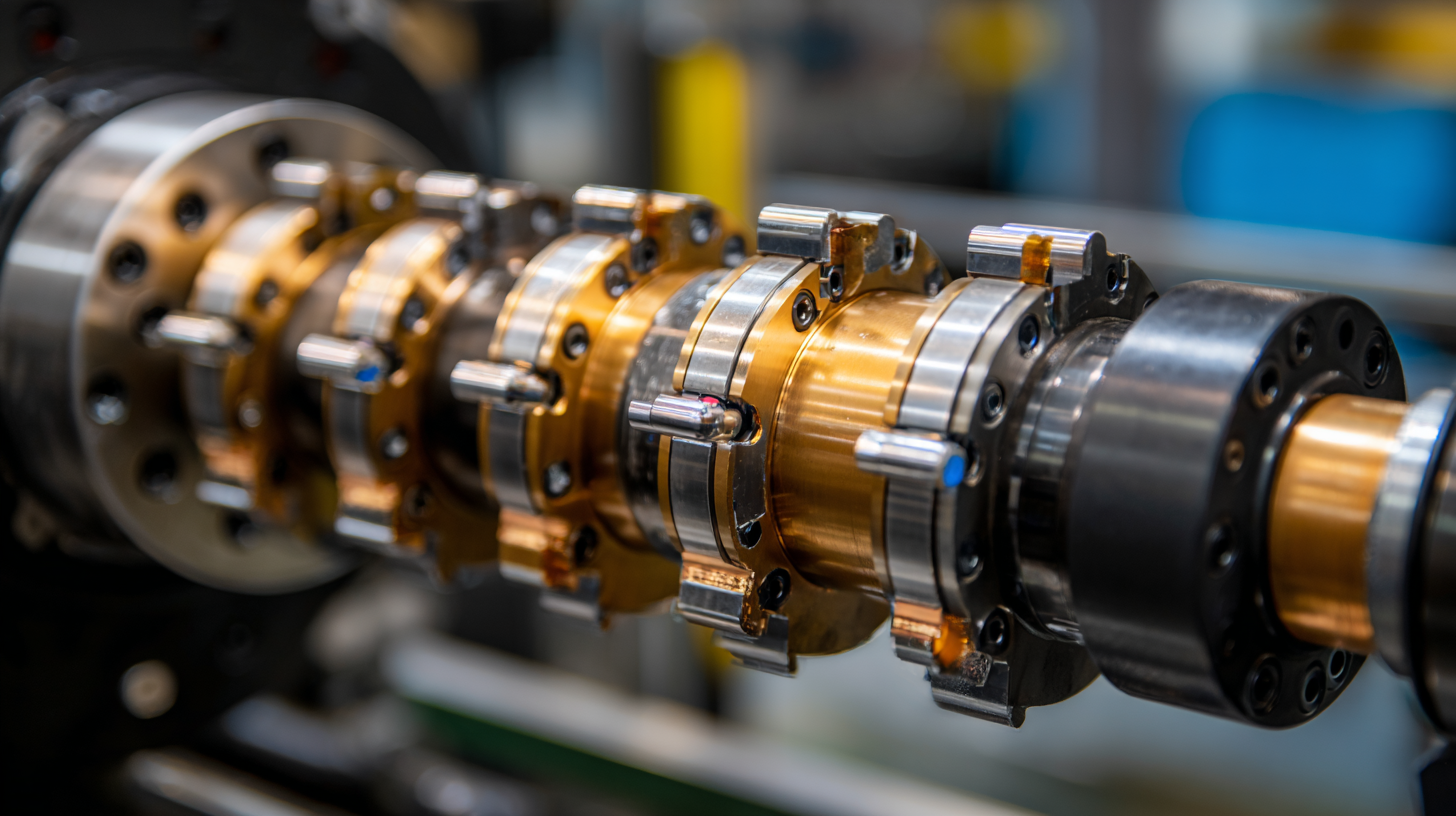

Boosting Productivity with Magnetic Grippers in Manufacturing Processes

Magnetic grippers have emerged as a revolutionary tool in manufacturing processes, significantly enhancing productivity and efficiency. These devices utilize magnetic forces to securely hold metal parts, allowing for faster handling and automated processes. By reducing the need for traditional clamping methods, manufacturers can streamline their workflows and decrease operation times, leading to quicker turnaround rates and increased output.

To fully leverage the benefits of magnetic grippers, it’s essential to consider the integration process. One useful tip is to assess the specific materials and weights of the products being handled to select the right type of magnetic gripper. Additionally, regular maintenance and inspection of the grippers ensure they remain in optimal condition, preventing downtime caused by equipment failures.

Another important consideration is the training of staff operating these systems. Ensuring that workers are well-versed in the operation of magnetic grippers can lead to better handling techniques and improved safety. Investing in training sessions not only boosts confidence but also encourages a culture of efficiency, further transforming productivity levels across the manufacturing landscape.

Reducing Downtime: The Impact of Magnetic Grippers on Operational Efficiency

Magnetic grippers have emerged as a transformative technology in various industrial sectors, significantly reducing downtime and enhancing operational efficiency. By utilizing powerful magnetic forces, these tools streamline the handling of materials, allowing for faster setup times and decreased manual labor. This reduction in human intervention not only minimizes the risk of errors but also accelerates the production process, facilitating a smoother workflow.

Magnetic grippers have emerged as a transformative technology in various industrial sectors, significantly reducing downtime and enhancing operational efficiency. By utilizing powerful magnetic forces, these tools streamline the handling of materials, allowing for faster setup times and decreased manual labor. This reduction in human intervention not only minimizes the risk of errors but also accelerates the production process, facilitating a smoother workflow.

Moreover, the reliability of magnetic grippers directly contributes to increased productivity levels. With quick attachment and release capabilities, manufacturers can swiftly switch between operations, thus optimizing their processes. This agility not only aids in meeting tight production schedules but also enhances overall workplace safety by decreasing the chances of accidents associated with manual lifting. As industries continue to embrace automation and advanced technologies, the integration of magnetic grippers signifies a substantial step towards achieving greater operational efficiency.

Cost Savings through Automation: The Financial Benefits of Magnetic Grippers

Magnetic grippers are revolutionizing the manufacturing landscape, offering significant cost savings through automation. According to a report by the International Federation of Robotics (IFR), companies that adopt automation solutions, including magnetic grippers, can reduce operational costs by up to 30%. This remarkable reduction primarily comes from increased productivity and a decrease in labor costs, allowing businesses to allocate resources more effectively.

Moreover, magnetic grippers enhance the efficiency of production lines, resulting in minimized cycle times. For instance, a study from McKinsey & Company revealed that automating tasks with high precision tools like magnetic grippers could lead to a 20% increase in throughput. This boost in production not only accelerates delivery times but also improves product quality, contributing to a robust bottom line. Industries utilizing these advanced grippers are reaping substantial financial rewards, making them a critical component of modern automation strategies.

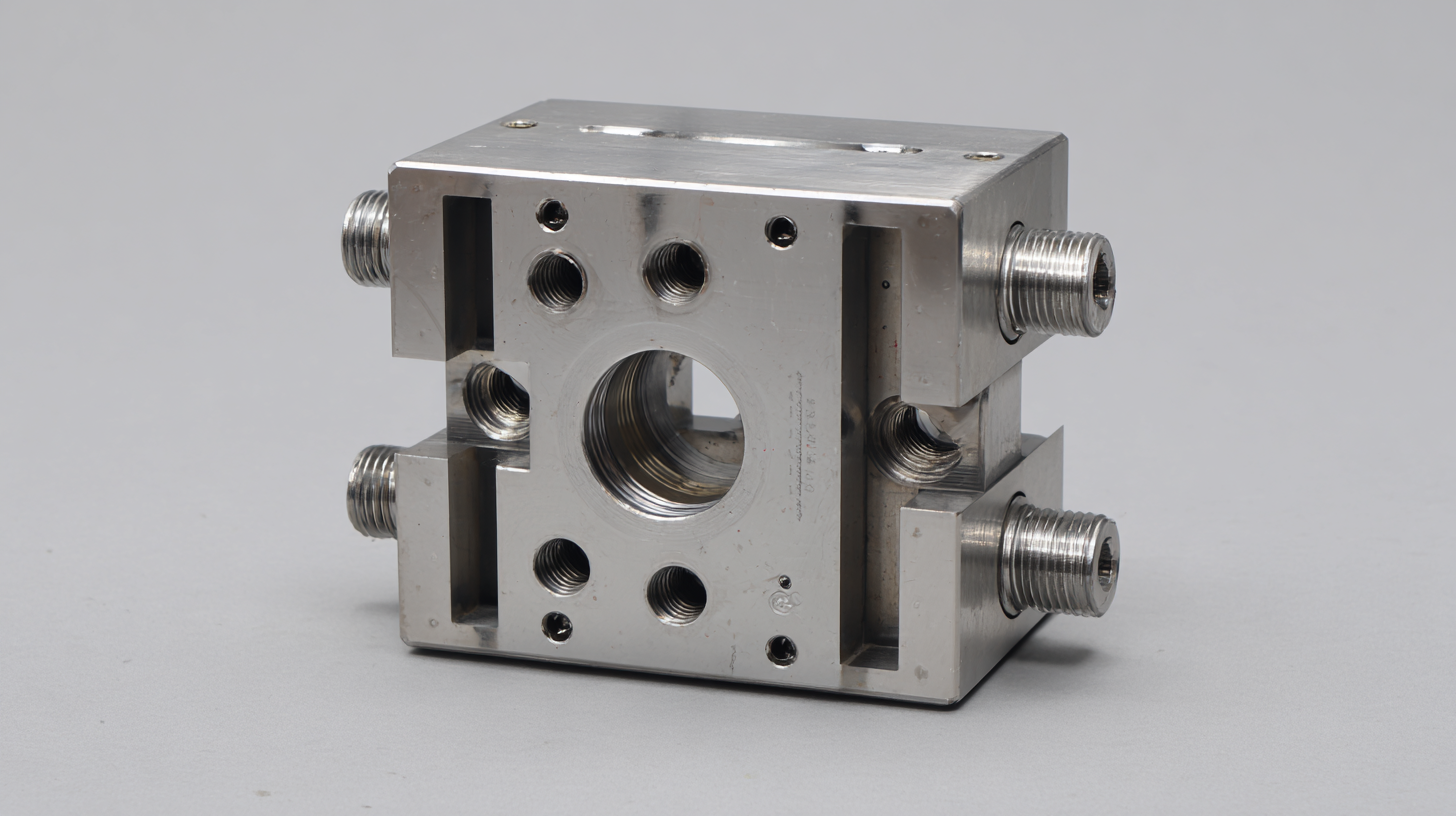

Versatility of Magnetic Grippers: Applications Across Various Industries

Magnetic grippers have emerged as essential tools in various industrial applications, showcasing remarkable versatility and efficiency. These devices utilize magnetic fields to grasp and manipulate metallic components, enhancing productivity in manufacturing, warehousing, and logistics. With the global market for magnetic grippers expected to grow significantly, industry reports highlight a projected CAGR of 7.5% over the next five years, driven by advancements in automation and robotics.

Across sectors such as automotive, electronics, and food processing, magnetic grippers are revolutionizing operational workflows. In the automotive industry, for instance, their ability to handle heavy metal parts safely and efficiently results in streamlined assembly lines. The electronics sector benefits from the non-contact gripping mechanism, which minimizes the risk of damage to sensitive components. Furthermore, in food processing, magnetic grippers ensure hygienic handling of metal materials, meeting stringent industry standards.

The integration of permanent magnet motors in these gripper systems is crucial for energy efficiency and compact design. As the demand for automation continues to rise, the ability of magnetic grippers to adapt to various tasks—whether in high-speed assembly or delicate product handling—positions them as indispensable tools in modern industry, driving unprecedented efficiency and operational reliability.