How to Choose the Right Magnetic Chuck for Your Machining Needs

Choosing the right magnetic chuck is a critical decision for any machining operation, as it directly impacts efficiency, precision, and the overall quality of the finished product. Magnetic chucks, known for their ability to securely hold ferromagnetic workpieces during machining processes, come in various types and sizes, each designed to cater to specific requirements. Understanding the unique characteristics and capabilities of different magnetic chucks is essential for optimizing production workflows and achieving desired machining outcomes. In this guide, we will explore key factors to consider when selecting magnetic chucks, including the nature of your workpieces, the type of machining operations you perform, and the environmental conditions of your workshop. By gaining insights into these considerations, you will be better equipped to choose the right magnetic chuck that not only meets your needs but also enhances your machining performance and productivity.

Choosing the right magnetic chuck is a critical decision for any machining operation, as it directly impacts efficiency, precision, and the overall quality of the finished product. Magnetic chucks, known for their ability to securely hold ferromagnetic workpieces during machining processes, come in various types and sizes, each designed to cater to specific requirements. Understanding the unique characteristics and capabilities of different magnetic chucks is essential for optimizing production workflows and achieving desired machining outcomes. In this guide, we will explore key factors to consider when selecting magnetic chucks, including the nature of your workpieces, the type of machining operations you perform, and the environmental conditions of your workshop. By gaining insights into these considerations, you will be better equipped to choose the right magnetic chuck that not only meets your needs but also enhances your machining performance and productivity.

Understanding Different Types of Magnetic Chucks for Machining

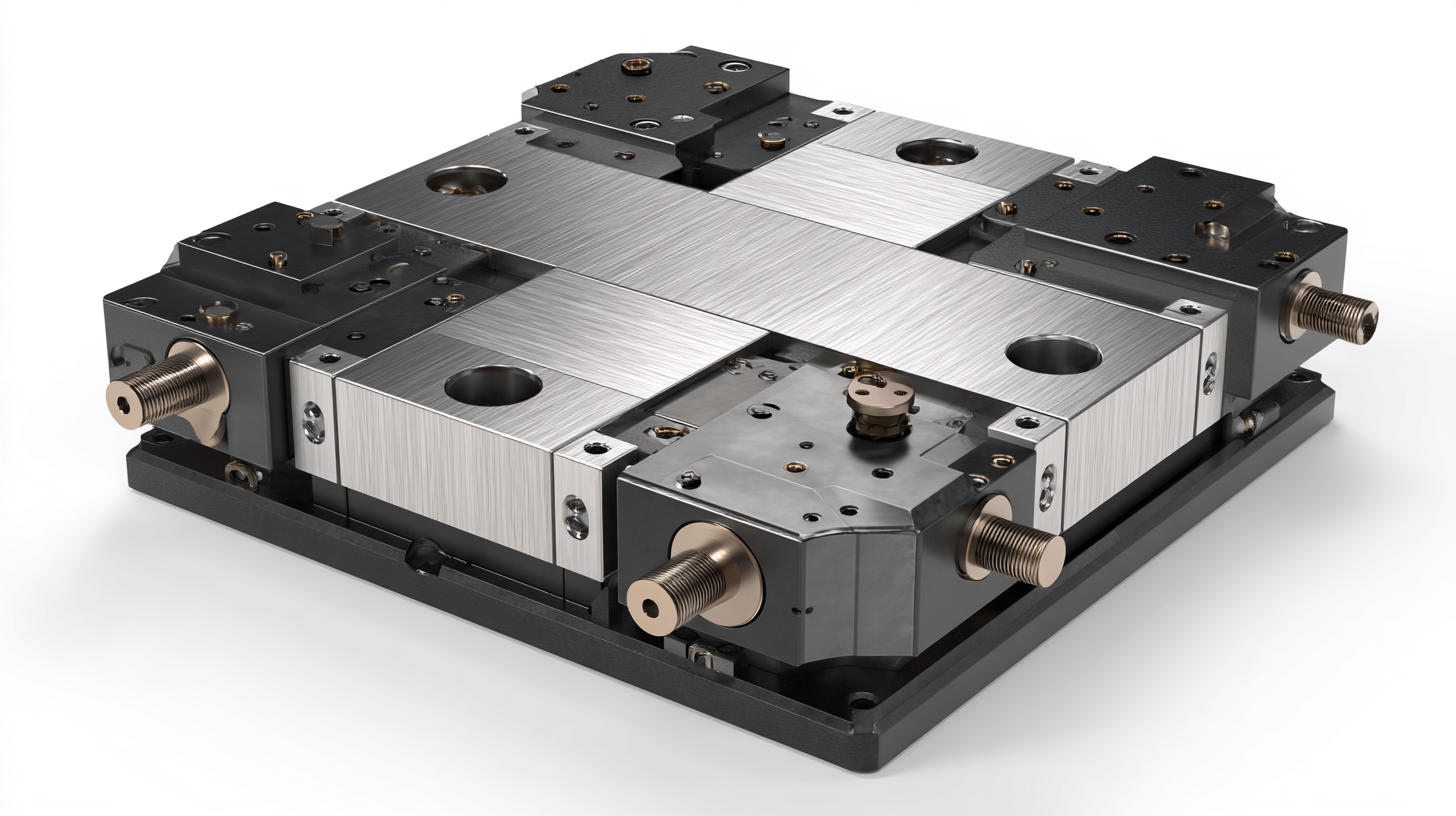

When selecting the right magnetic chuck for machining, it's essential to understand the various types available and their specific applications. Magnetic chucks can be classified primarily into permanent magnetic chucks and electromagnetic chucks. Permanent magnetic chucks utilize permanent magnets to create a solid holding force, making them suitable for applications requiring a stable and continuous grip, even in the event of power loss. They are often favored for their simplicity and reliability in rough machining operations.

On the other hand, electromagnetic chucks offer adjustable holding power, allowing for better control in various machining processes. These chucks are best for complex workpieces that may require variable pressure during machining or for tasks that switch frequently between different jobs. They provide enhanced versatility, especially in environments where diverse materials and sizes are involved. Understanding these distinctions is crucial for choosing a magnetic chuck that aligns with your specific machining needs, ensuring effectiveness and precision in your operations.

How to Choose the Right Magnetic Chuck for Your Machining Needs

| Type of Magnetic Chuck |

Application |

Holding Force (N) |

Size (mm) |

Price Range (USD) |

| Permanent Magnetic Chuck |

Milling, Grinding |

400 - 600 |

100 x 100 |

$150 - $300 |

| Electromagnetic Chuck |

Milling, Drilling |

800 - 1200 |

200 x 200 |

$300 - $600 |

| Electro Permanent Magnetic Chuck |

Precision Machining |

1000 - 1500 |

300 x 300 |

$500 - $1000 |

| Magnetic Vise |

Small Parts Grinding |

200 - 400 |

150 x 100 |

$80 - $150 |

Key Factors to Consider When Choosing a Magnetic Chuck

When selecting the right magnetic chuck for your machining needs, several key factors must be considered to ensure optimal performance and productivity. First and foremost, the size and configuration of the magnetic chuck should match the dimensions and the shape of your workpiece. A chuck that is too small may not provide adequate holding force, while one that is too large can lead to inefficient clamping and wasted space.

Another important consideration is the type of material you are working with. The magnetic chuck must be compatible with the material's magnetic properties to ensure effective holding. Additionally, the style of machining can influence your choice; for instance, precision applications may require chucks designed for fine adjustments, while heavy-duty operations benefit from robust chucks designed to withstand higher forces. Lastly, evaluating the surface finish of the chuck is essential, as it affects the contact area with the workpiece and, ultimately, the holding power. Investing time in assessing these factors can lead to improved machining results and operational efficiency.

Assessing Strength and Holding Power for Your Specific Applications

When selecting a magnetic chuck for your machining needs, assessing the strength and holding power is crucial to ensure optimal performance in specific applications. The holding power of a magnetic chuck is determined by its magnetic strength, which can vary based on the design and material composition. Consider factors such as the weight and material of the workpiece, as well as the machining process involved. A stronger magnetic chuck may be necessary for heavy or dense materials, while lighter materials can be securely held with less strength.

When selecting a magnetic chuck for your machining needs, assessing the strength and holding power is crucial to ensure optimal performance in specific applications. The holding power of a magnetic chuck is determined by its magnetic strength, which can vary based on the design and material composition. Consider factors such as the weight and material of the workpiece, as well as the machining process involved. A stronger magnetic chuck may be necessary for heavy or dense materials, while lighter materials can be securely held with less strength.

Additionally, it's important to evaluate the type of magnetic chuck, whether it is permanent or electro-permanent. Permanent chucks typically offer consistent holding power and are less susceptible to power failure, making them suitable for long-running jobs. On the other hand, electro-permanent chucks provide a switchable option, allowing for enhanced versatility across different machining tasks. Assessing your specific applications' requirements, such as precision tolerances and desired machining speeds, will help you choose the right magnetic chuck that guarantees both efficiency and reliability in your operations.

Material Compatibility and Its Impact on Chuck Performance

When selecting a magnetic chuck for machining operations, material compatibility is a crucial factor that directly influences chuck performance. Different materials exhibit varying magnetic properties, which can affect how well the chuck holds the workpiece. For instance, ferromagnetic metals like iron and steel are highly conducive to magnetic attraction, providing a strong grip and stability during machining. Conversely, non-ferromagnetic materials such as aluminum or brass require specialized chucks that incorporate advanced magnetic systems or additional securing methods to maintain precision and safety.

Furthermore, the characteristics of the material being machined also play a significant role in the choice of the magnetic chuck. Soft materials might create less wear on the chuck surface, prolonging its life, while harder materials could lead to increased wear and potential damage. This necessitates selecting a chuck designed to handle specific loads and surface conditions. Understanding these compatibility factors ensures not only optimal performance but also enhances machining accuracy and efficiency, ultimately leading to better results in production processes.

Maintenance Tips to Extend the Life of Your Magnetic Chuck

When it comes to maintaining your magnetic chuck, several key practices can help extend its lifespan and optimize your machining operations. Regular cleaning is essential to prevent debris accumulation that can impair the magnetic force and overall performance. A simple routine of wiping down the chuck surface and ensuring the relevant areas are free from dust and oil will go a long way in maintaining its effectiveness. Additionally, checking for any signs of wear or damage periodically can help catch issues before they escalate, ensuring consistent performance.

Another critical aspect of maintenance is ensuring the chuck is correctly calibrated and that the magnetic force is consistent. If your magnetic chuck isn’t providing the necessary holding power, it can lead to decreased precision in your machining tasks. Implementing regular checks and calibrations can enhance accuracy and prevent costly mistakes. Moreover, integrating new technologies, such as heat-shrink tool holding, can optimize tool use. By significantly reducing tool runout and enhancing cut quality, these advances not only improve tool life but also help in reducing overall costs, thereby complementing your magnetic chuck maintenance efforts effectively.

Magnetic Chuck Selection and Maintenance

This chart illustrates key attributes to consider when selecting a magnetic chuck for machining needs: the holding force in Newtons (N), the expected lifespan in years, and the recommended maintenance frequency in months. Proper understanding of these factors can enhance performance and longevity.