The Future of Robotics How Magnetic Grippers are Revolutionizing Automation

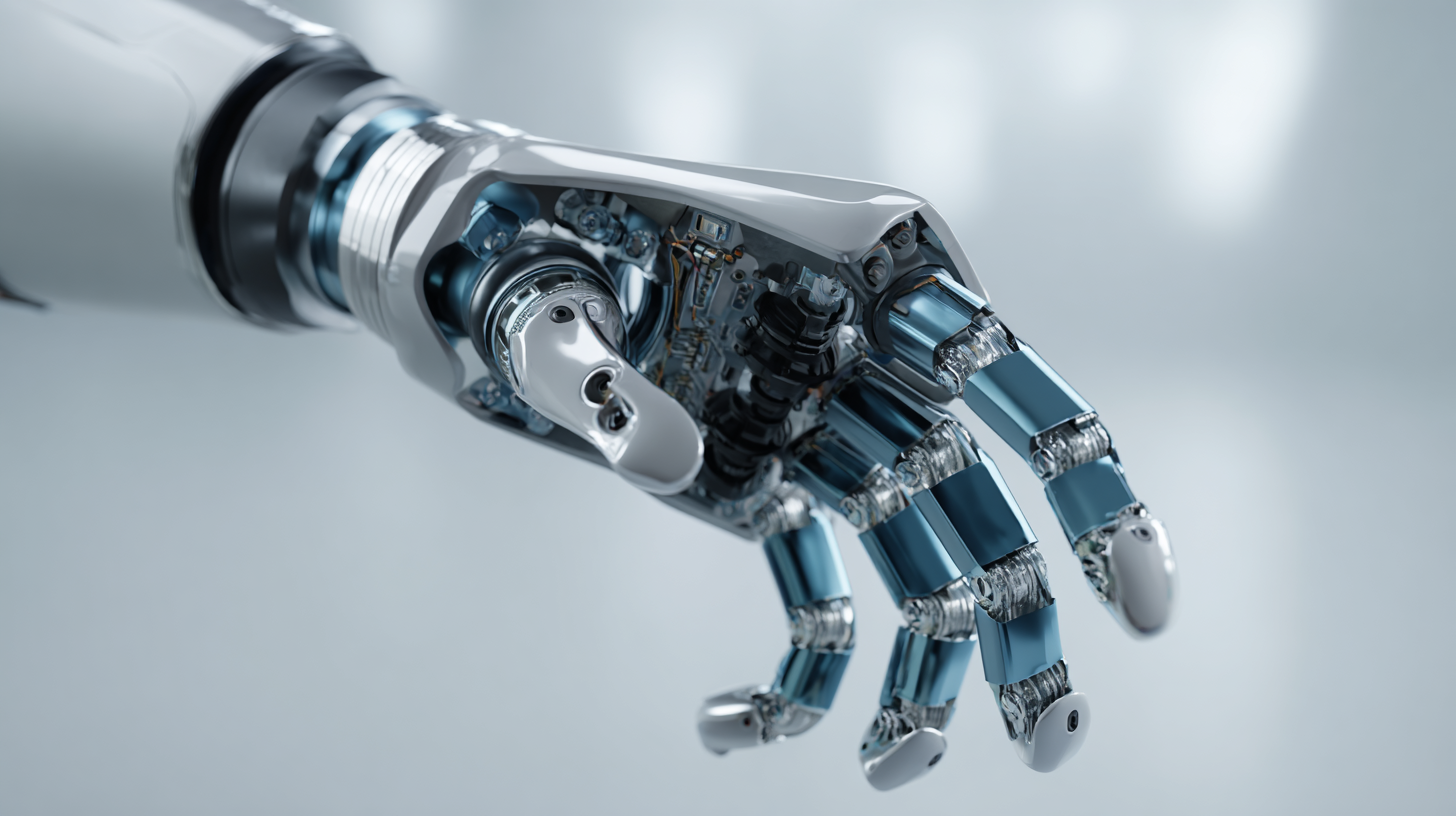

In the rapidly evolving landscape of automation, the advent of advanced technologies continues to reshape industries and enhance operational efficiency. Among these innovations, the Magnetic Gripper stands out as a groundbreaking tool that is transforming robotic capabilities. This powerful device offers unparalleled versatility in handling a diverse array of materials with precision and ease.

Its ability to securely grip and manipulate objects without the need for traditional mechanical clamping methods not only streamlines processes but also reduces the risk of damage to delicate items.

As industries from manufacturing to logistics embrace the potential of Magnetic Grippers, understanding their functionality and application becomes essential. This article will explore how Magnetic Grippers are revolutionizing automation, examining their technological advancements, practical implementations, and the future they promise for robotics in various sectors.

Understanding Magnetic Grippers and Their Functionality

Magnetic grippers are making significant strides in the field of automation, offering unique advantages over traditional gripping systems. These devices utilize magnetic fields to securely hold ferromagnetic objects, thereby streamlining operations in manufacturing and logistics. According to a report by MarketsandMarkets, the global market for magnetic grippers is expected to grow at a CAGR of 7.5% between 2023 and 2030, underscoring the increasing adoption of these technologies across various industries. This technology not only enhances the efficiency of material handling but also reduces wear and tear on equipment, contributing to lower maintenance costs.

The functionality of magnetic grippers hinges on their ability to manipulate objects without mechanical parts that can wear out or require frequent calibration. This is particularly beneficial in environments where precision and speed are paramount. A study by the Robotics Industry Association highlighted that implementing magnetic grippers can enable a 30% increase in picking speed compared to traditional methods, ultimately accelerating production lines. This technological leap empowers manufacturers to meet growing consumer demands while maintaining high levels of safety and productivity in their operations.

The Advantages of Magnetic Grippers in Industrial Automation

With the increasing demand for efficiency and precision in industrial automation, magnetic grippers have emerged as a significant advancement in robotics technology. These innovative tools provide multiple advantages, especially in applications like sheet metal handling and automotive manufacturing. Their ability to securely hold ferromagnetic items reduces the risk of damage during transport, making them invaluable for processes that require quick yet gentle handling of materials.

Tips: When selecting a gripper for your application, consider the weight and size of the parts being handled. Magnetic grippers excel in applications with varying shapes, as they can adapt to different surface areas.

Additionally, the trend towards hybrid tooling solutions—combining magnetic functionality with other gripping mechanisms—offers further customization for complex tasks. This versatility allows companies to streamline operations while maintaining high standards of precision and efficiency. As industries continue to explore the potential of magnetic grippers, it's clear they are reshaping the landscape of automation.

Tips: Keep an eye on maintenance requirements; regular checks can enhance the lifespan of your grippers and prevent unexpected downtime.

Applications of Magnetic Grippers in Various Industries

Magnetic grippers are transforming the landscape of automation across various industries by offering precise and versatile handling solutions. In manufacturing, these devices streamline assembly lines by efficiently picking and placing components, from metal sheets to delicate electronics. Their ability to operate without the need for complex mechanical parts not only reduces maintenance but also enhances productivity. Moreover, the magnetic grip can be easily adjusted, allowing for the handling of objects of varying sizes and weights, making them indispensable in high-volume production.

In the field of logistics, magnetic grippers facilitate the automation of material handling processes. They enable robots to swiftly move pallets and packages with ease, minimizing the risk of damage during transport. In the automotive industry, these grippers play a critical role in assembly operations, where precision is paramount. Additionally, magnetic grippers are gaining traction in the food industry, where they are employed in the packaging process to ensure hygiene standards while efficiently moving products. As industries continue to adopt automation technologies, magnetic grippers are proving to be vital tools for enhancing efficiency and safety.

The Future of Robotics: How Magnetic Grippers are Revolutionizing Automation

| Industry |

Application |

Benefits |

Examples of Use Cases |

| Automotive |

Assembly Line Handling |

Increased speed and reduced handling damage |

Component placement and transfer |

| Electronics |

Precise Component Assembly |

Enhanced accuracy in delicate tasks |

Circuit board assembly |

| Food Industry |

Packaging and Sorting |

Hygienic handling and efficient operations |

Packing goods and assembly |

| Logistics |

Pallet Handling |

Optimized space utilization and workload |

Automated warehousing systems |

| Construction |

Material Manipulation |

Increased safety and efficiency |

Moving large components and fixtures |

Future Trends: Enhancements in Magnetic Gripper Technology

Recent advancements in magnetic gripper technology have paved the way for significant enhancements in automation across various industries. According to a report by MarketsandMarkets, the global robotics market is expected to reach $214 billion by 2030, with automation becoming increasingly essential for manufacturing processes. Magnetic grippers are at the forefront of this revolution, offering flexible and efficient handling solutions that adapt seamlessly to different materials and shapes. This adaptability not only reduces cycle times but also minimizes the risk of damage to delicate components, making them invaluable in environments like electronics assembly and automotive manufacturing.

Future trends indicate a strong inclination towards integrating artificial intelligence (AI) in magnetic gripper systems. A study by Technavio suggests that the AI-based robotics market is anticipated to grow at a CAGR of around 40% between 2021 and 2025. By incorporating AI, magnetic grippers can achieve enhanced precision and responsiveness, allowing them to execute complex tasks with minimal human intervention. Additionally, advancements in materials science are leading to lighter and more robust magnetic materials, which further improve the performance and energy efficiency of robotic systems. As these technologies evolve, magnetic grippers are set to play a crucial role in the next wave of automation, driving increased productivity and flexibility in various sectors.

The Future of Robotics: Enhancements in Magnetic Gripper Technology

This bar chart presents a comparison of magnetic gripper technology metrics for 2023 and projected values for 2025. As seen, enhancements in holding force and grip speed are significant, while cost is expected to decrease, indicating a promising future for automation.

Integrating Magnetic Grippers into Existing Robotic Systems

The integration of magnetic grippers into existing robotic systems is transforming the landscape of automation. By enabling robots to effortlessly handle a variety of materials and shapes, these advanced grippers enhance operational flexibility and efficiency. Magnetic grippers utilize electromagnetic force to secure items without the need for traditional mechanical components, simplifying the design and dramatically improving the speed of the handling process. This technology allows robots to swiftly switch between tasks, making them indispensable in fast-paced environments such as manufacturing and logistics.

Tips: When considering the integration of magnetic grippers, assess the weight and material properties of the items being handled. Ensuring your robotic system is compatible with electromagnetic technology will minimize setbacks during implementation. Additionally, investing in adaptable magnetic grippers can maximize versatility across different applications, leading to a lower total cost of ownership.

As industries strive for greater efficiency, incorporating magnetic grippers not only streamlines operations but also reduces the risk of damage to delicate items. The ease of control provided by these grippers allows operators to enhance precision, ultimately improving the overall quality of production. This integration can empower companies to meet the increasing demand for faster and more reliable automation solutions in today’s competitive market.