Unlocking the Science: How Gripper Magnets Enhance Precision in Robotics and Industrial Automation

In the rapidly evolving landscape of robotics and industrial automation, precision is paramount for efficiency and productivity. One of the groundbreaking innovations enhancing this precision is the use of gripper magnetic systems. These devices leverage magnetic forces to securely hold and manipulate objects with incredible accuracy, thus redefining the paradigms of automation. As industries increasingly adopt sophisticated robotics for various applications, understanding the science behind gripper magnets becomes essential.

This article delves into how gripper magnetic technology is not only optimizing performance but also providing practical tips for implementation across various industrial settings. By exploring the mechanics and benefits of these systems, we unlock new possibilities for achieving greater precision, reliability, and versatility in automated tasks.

The Role of Gripper Magnets in Enhancing Robotic Precision and Efficiency

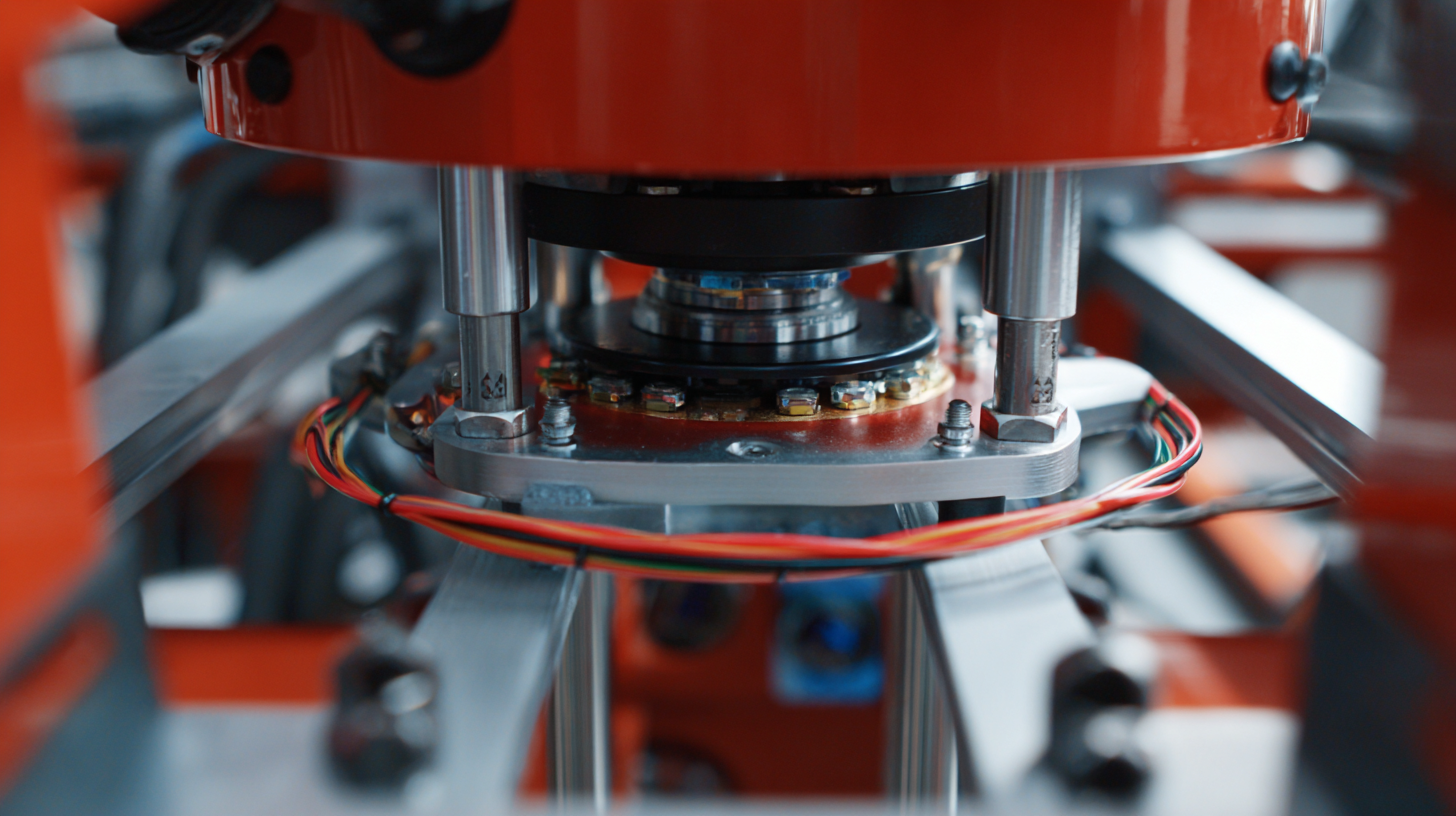

Gripper magnets play a crucial role in enhancing the precision and efficiency of robotic systems used in various industrial applications. These magnets are designed to securely hold and manipulate objects with a high degree of accuracy. By utilizing magnetic force, gripper magnets can adapt to different shapes and sizes of items, allowing robots to perform complex tasks without the risk of dropping or misplacing components. This adaptability significantly reduces the cycle time of operations, leading to improved productivity in assembly lines and manufacturing environments.

Furthermore, the integration of gripper magnets in robotics promotes a seamless collaboration between machines and human operators. With their ability to provide consistent grip strength, these magnets enable robots to handle delicate materials without causing damage, thus ensuring higher quality outcomes. As automation continues to evolve, the precision offered by gripper magnets is becoming increasingly vital, paving the way for smarter and more efficient industrial processes that can respond dynamically to changing demands. This advancement not only streamlines operations but also minimizes human error, further solidifying the importance of gripper magnets in the future of robotics and automation.

Understanding the Basics: How Gripper Magnets Function in Automation Systems

Gripper magnets play a crucial role in automation systems, enhancing the precision and efficiency of robotic operations. These specialized magnets are designed to securely grasp and manipulate various objects, ranging from small components to heavy machinery parts. By utilizing magnetic fields, gripper magnets can provide a reliable gripping solution without the need for complex mechanical systems, which can often lead to increased wear and tear.

Understanding the underlying mechanics of these magnets is essential for optimizing their performance in diverse applications.

Tips: When selecting gripper magnets for your automation system, consider the weight and material properties of the objects being handled. Ensuring that the magnet's strength matches the requirements of your operation can greatly improve overall efficiency and prevent operational failures.

Moreover, the design flexibility of gripper magnets allows them to be integrated seamlessly into robotic arms and automated systems. They can be tailored to accommodate various shapes and sizes of items, ensuring a secure hold during transportation and assembly processes. This adaptability not only enhances the robots' capabilities but also contributes to a safer working environment by minimizing the risk of dropped items.

Tips: Regular maintenance of gripper magnets is essential for sustained performance. Keep the magnetic surfaces clean and check for wear or damage to prolong their operational lifespan.

Industry Data: The Impact of Magnetic Grippers on Production Rates and Accuracy

Magnetic grippers have emerged as a transformative technology in the fields of robotics and industrial automation. Their ability to enhance production rates and accuracy stems from the unique way they manipulate objects. By generating a magnetic field, these grippers can securely hold items of varying shapes and sizes without the need for mechanical clamps. This versatility not only improves efficiency but also minimizes the risk of damage to delicate components during handling.

Magnetic grippers have emerged as a transformative technology in the fields of robotics and industrial automation. Their ability to enhance production rates and accuracy stems from the unique way they manipulate objects. By generating a magnetic field, these grippers can securely hold items of varying shapes and sizes without the need for mechanical clamps. This versatility not only improves efficiency but also minimizes the risk of damage to delicate components during handling.

Incorporating magnetic grippers into production lines has shown significant improvements in overall performance. Data indicates that companies utilizing these devices experience faster cycle times and reduced downtime, leading to higher output rates. For instance, studies reveal that industries employing magnetic grippers have seen a 30% increase in productivity while maintaining precision levels that meet stringent quality standards. The impact is notably pronounced in applications requiring the automated transfer of lightweight or fragile parts.

Tips: When implementing magnetic grippers, consider the strength of the magnetic field relative to the materials being handled to prevent slippage. Additionally, integrating sensors with magnetic grippers can provide real-time feedback, enhancing control and further ensuring accuracy throughout the production process. Regularly training staff on the optimal use of these systems can also maximize their effectiveness and longevity.

Comparative Analysis: Gripper Magnets vs. Traditional Gripping Mechanisms in Robotics

Gripper magnets are revolutionizing the field of robotics, particularly when compared to traditional gripping mechanisms such as mechanical clamps and pneumatic actuators.

A study conducted by MarketsandMarkets forecasts that the global robotics gripper market will reach $2.8 billion by 2025, driven primarily by the demand for automation across various industries.

Gripper magnets offer a significant advantage in precision handling, with the ability to securely attach and release items without mechanical pressure, reducing the risk of damage to delicate parts. This non-contact approach results in greater efficiency, as evidenced by data from a recent report by Research and Markets, which indicates that using magnetic grippers can enhance operational speed by up to 30% in assembly lines.

Moreover, gripper magnets are lighter and more compact than traditional mechanisms, enabling robots to maneuver in tighter spaces and perform complex tasks with greater agility.

The flexibility of magnetic gripping systems also allows for quick adaptation to different objects, minimizing downtime and increasing productivity.

According to a report by Allied Market Research, the deployment of electromagnetic grippers is expected to grow at a CAGR of 9.5% from 2023 to 2030, proving their increasing relevance in industrial automation.

As industries continue to evolve, the preference for gripper magnets over conventional methods will likely increase, reflecting a significant shift in how precision tasks are approached in robotics.

Future Trends: Innovations in Gripper Magnet Technology for Enhanced Automation Solutions

The future of automation is increasingly intertwined with advancements in gripper magnet technology. As industries strive for greater efficiency and precision, innovative gripper systems are being developed to address the dynamic challenges of robotics and automated tasks. Emerging technologies, such as smart magnets that can adjust their grip strength based on the weight or shape of the object, are transforming how robots handle diverse materials, which is crucial for sectors ranging from manufacturing to logistics.

One of the key trends in this field is the integration of artificial intelligence with gripper magnet systems. This combination allows for real-time adaptability, where robots can learn from their environment and adjust their gripping techniques accordingly. Furthermore, developments in lightweight materials and compact designs are enhancing the usability of gripper magnets, making them more accessible for a wider range of applications. As these innovations continue to evolve, we can expect significant improvements in automation solutions, leading to greater productivity and precision in various industries.