What is Magnet Grinding and How is it Used in Manufacturing Processes

Magnet Grinding is an innovative machining process that utilizes magnetic forces to enhance grinding efficiency and precision in manufacturing. This technique has gained considerable attention in the industry due to its ability to produce high-quality finishes while minimizing waste and operational costs. As manufacturing processes continue to evolve with technological advancements, understanding the role of Magnet Grinding becomes increasingly vital.

According to Dr. Emily Carter, a renowned expert in the field of advanced manufacturing, “Magnet Grinding revolutionizes the way we approach material removal by combining traditional methods with modern magnetic technology.” Her insights underscore the transformative potential of this process in improving productivity and product quality. As manufacturers strive to meet the growing demand for precision-engineered components, the adoption of Magnet Grinding techniques is likely to become more prevalent, paving the way for enhanced capabilities and efficiency in manufacturing workflows.

This article will explore the fundamentals of Magnet Grinding, its applications in various industries, and how it can be seamlessly integrated into existing manufacturing processes to drive innovation and performance.

What is Magnet Grinding?

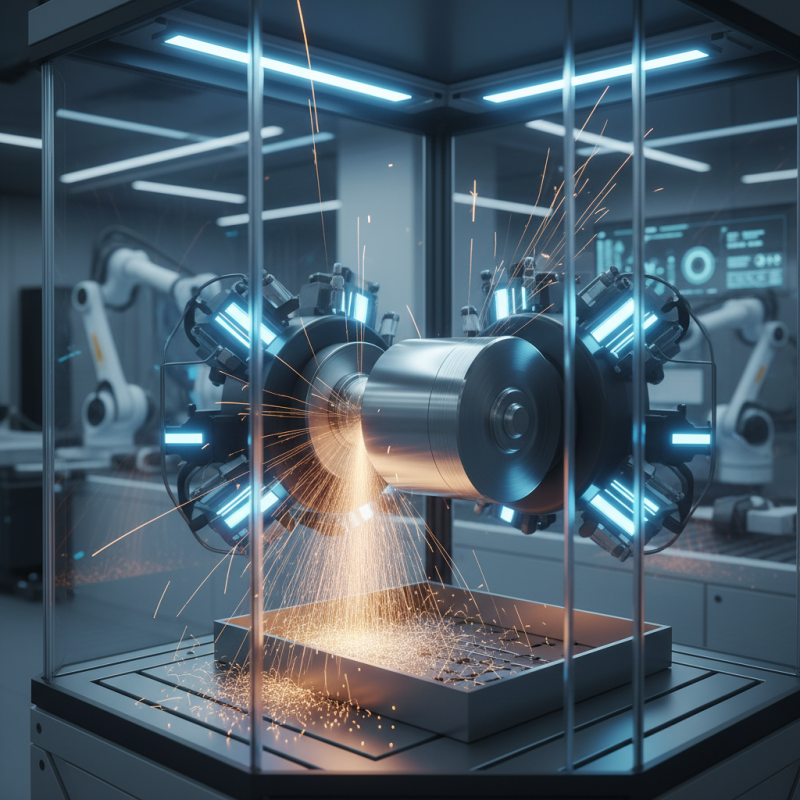

Magnet grinding, also known as magnetic abrasive machining, is an innovative process primarily utilized in the manufacturing sector for precision surface finishing. This technique employs magnetic fields to manipulate fine abrasive materials, allowing for highly efficient and effective grinding of complex geometries and hard-to-reach surfaces. By aligning the abrasive particles using magnetic forces, manufacturers can achieve enhanced control over the grinding process, resulting in superior surface finishes and reduced wear on grinding tools.

According to a report from the International Journal of Advanced Manufacturing Technology, magnet grinding has shown to improve machining efficiency by up to 30% compared to traditional grinding methods. This is largely attributed to the uniform application of pressure across the workpiece, which minimizes the risk of deformation and ensures a consistent finish. The process is particularly valuable in industries such as aerospace and automotive, where precision components require stringent adherence to tolerances and surface quality.

The adoption of magnet grinding in manufacturing processes aligns with the growing demand for advanced machining technologies that enhance productivity while lowering operational costs. As reported by Research and Markets, the global market for advanced manufacturing technologies is projected to grow at a CAGR of 10.6% from 2021 to 2026, underscoring the industry's shift towards more innovative solutions like magnet grinding. This trend not only enhances production capabilities but also contributes to sustainable manufacturing practices through reduced material waste and energy consumption.

The Principles of Magnet Grinding Technology

Magnet grinding is an advanced manufacturing process that leverages magnetic force to enhance material removal efficiency in machining. The technique relies on magnetic abrasives to polish, grind, or finish the workpiece surface, providing a precision that traditional grinding methods may struggle to achieve. According to a recent industry report by the International Journal of Advanced Manufacturing Technology, magnet grinding can increase the removal rate of material by up to 40% compared to conventional grinding processes, significantly reducing production time and improving the overall efficiency of manufacturing operations.

The principles behind magnet grinding technology are grounded in magnetostatics and the interaction between magnetic fields and ferromagnetic particles. By applying a magnetic field, abrasive materials are manipulated to form a dense, flexible grinding brush that conforms to the contours of the workpiece. This adaptability not only enhances surface finish but also minimizes the risk of damage to intricate features. Data from the American Society of Mechanical Engineers (ASME) indicates that processes utilizing magnet grinding can achieve surface roughness values below 0.1 micrometers, promoting higher quality standards in industries such as aerospace and automotive manufacturing. The ability to fine-tune the grinding process through variable magnetic field strengths further emphasizes the versatility and precision offered by this technology.

Magnet Grinding Process Efficiency

Applications of Magnet Grinding in Manufacturing

Magnet grinding is an innovative manufacturing process that leverages the power of magnetic fields to enhance material removal and surface finishing. One of the primary applications of magnet grinding is in the production of precision components in industries such as aerospace, automotive, and electronics. By using magnetic abrasive particles, manufacturers can achieve a high degree of accuracy and smoothness on complex geometries, which is essential for components that require tight tolerances and superior surface characteristics.

Another significant application of magnet grinding is in the finishing of hard materials, including metals and ceramics. The magnetic field mobilizes abrasive particles, allowing them to surround the workpiece and engage with its surface effectively. This technique not only promotes efficient material removal but also minimizes tool wear, extending the lifespan of grinding equipment. As a result, magnet grinding is increasingly utilized for producing sharp cutting edges in tooling and for refining surfaces to meet the stringent quality standards of modern manufacturing sectors.

Advantages of Magnet Grinding Over Traditional Methods

Magnet grinding is an innovative machining technique that employs magnetic forces to assist in the grinding process. One of the primary advantages of magnet grinding over traditional methods is the enhanced precision it offers. By utilizing magnetic fields, this technique can maintain better control over the workpiece, minimizing vibrations and fluctuations that often impair the quality of the finish in conventional grinding methods. This improved stability allows for tighter tolerances and a more uniform surface finish, making it ideal for high-precision manufacturing applications.

Additionally, magnet grinding is more efficient than traditional grinding techniques. The magnetic clamping system securely holds the workpiece in place, which reduces setup time and increases throughput in manufacturing processes. This efficiency also translates into reduced wear on grinding wheels, leading to lower maintenance costs and extended tool life. Furthermore, the elimination of physical clamps not only speeds up the grinding process but also decreases the risk of damage to the workpiece, further enhancing the overall effectiveness of magnet grinding in modern manufacturing environments.

What is Magnet Grinding and How is it Used in Manufacturing Processes - Advantages of Magnet Grinding Over Traditional Methods

| Dimension |

Magnet Grinding |

Traditional Grinding |

| Process Mechanism |

Uses magnetic force for grinding |

Uses mechanical force for grinding |

| Setup Time |

Shorter setup time |

Longer setup time |

| Precision |

Higher precision |

Variable precision |

| Material Removal Rate |

Higher removal rate |

Lower removal rate |

| Cost Efficiency |

More cost-effective |

Higher operational cost |

| Environmental Impact |

Lower waste generation |

Higher waste generation |

Future Developments in Magnet Grinding Techniques

Future developments in magnet grinding techniques hold significant promise for enhancing manufacturing processes across various industries. One of the key areas of innovation is the integration of advanced materials and nanotechnology. These advancements enable the production of finer and more precise magnet grinding tools, which can lead to improved efficiency and reduced wear on machinery. As manufacturers increasingly seek sustainable practices, research into eco-friendly grinding compounds is also gaining traction, offering the potential to minimize environmental impact while maintaining performance.

Moreover, automation and smart technologies are poised to revolutionize magnet grinding methods. The adoption of AI-driven algorithms can optimize grinding parameters in real time, allowing for greater precision and consistency in the production process. Additionally, the implementation of machine learning can provide insights into wear patterns and maintenance needs, ultimately extending the lifespan of grinding equipment and reducing downtime. As these developments continue to unfold, the manufacturing landscape will likely witness a shift toward more intelligent and adaptable magnet grinding solutions, further enhancing productivity and quality in various applications.