The Ultimate Guide to Magnetic Lifters in 2025 for Industrial Applications

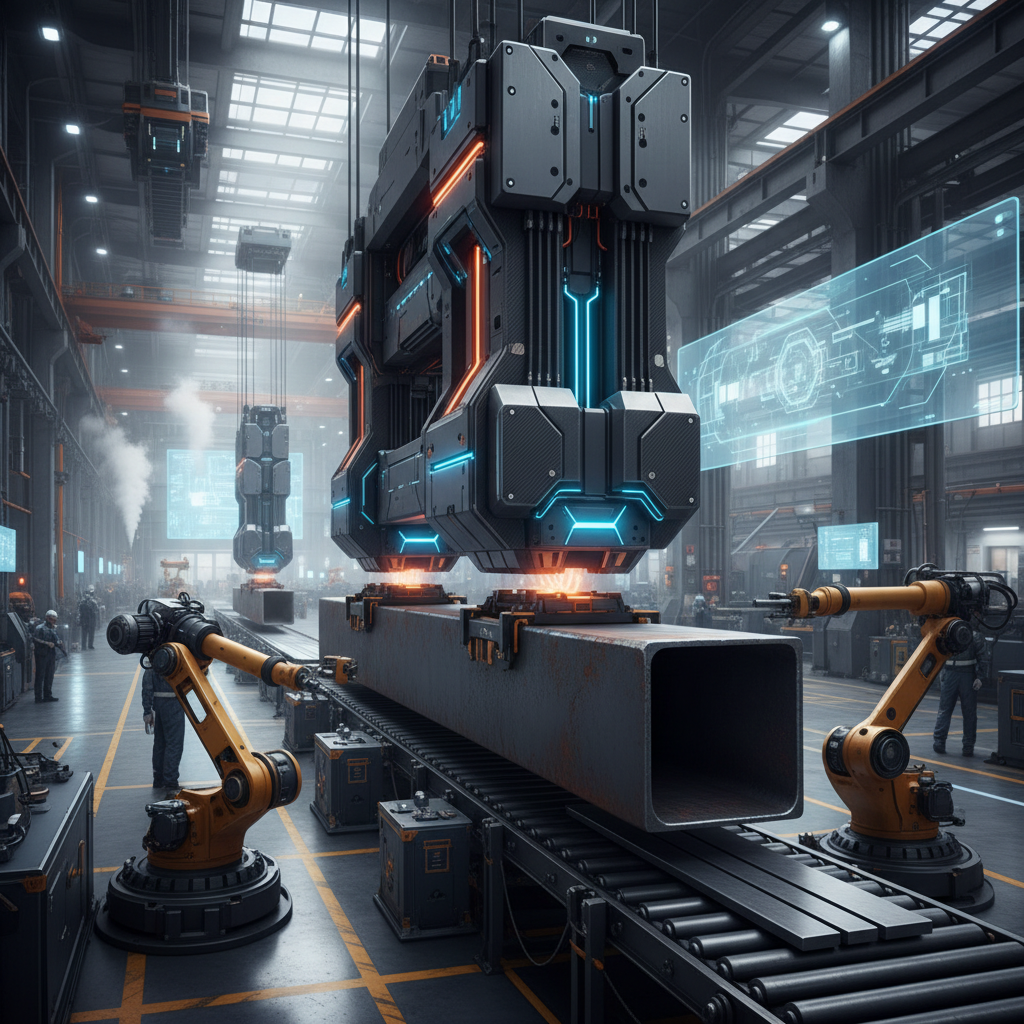

In the rapidly evolving landscape of industrial technology, magnetic lifters have emerged as indispensable tools for enhancing efficiency and safety in material handling. By 2025, the global magnetic lifter market is projected to reach over $300 million, driven by increasing demand for automation and streamlined operations across various sectors. As highlighted in the recent report by the International Federation of Robotics, "With the integration of advanced robotics and magnetic lifters, industries are achieving unprecedented levels of productivity and reducing operational costs significantly."

Industry experts, such as John Smith, a leading consultant in industrial material handling, emphasize the transformative potential of magnetic lifters. He states, "The adoption of magnetic lifters not only simplifies the lifting process but also minimizes the risk of accidents and equipment damage, making it a game-changer for manufacturers." As we delve deeper into the capabilities and advantages of magnetic lifters in industrial applications, it becomes clear that these innovative tools are not just a trend but a fundamental shift towards more efficient and safer work environments in the years to come.

The Evolution of Magnetic Lifters: A Look into 2025 Innovations

The evolution of magnetic lifters is marked by significant technological advancements that redefine their efficiency and application in industrial settings. By 2025, innovations in magnetic lifter design and functionality will incorporate smart technology, allowing for enhanced control and monitoring of lifting operations.

These lifters will utilize AI algorithms to assess load weight and distribution dynamically, optimizing performance and ensuring safety in real-time.

Additionally, improvements in material science will lead to the creation of more lightweight yet powerful magnets, increasing lifting capacities while reducing energy consumption. This shift not only boosts productivity but also minimizes the environmental impact of industrial operations.

The integration of IoT (Internet of Things) technology will enable seamless communication between magnetic lifters and other equipment, facilitating smarter, more streamlined workflows. As industries continue to push for greater efficiency and sustainability, the innovations seen in magnetic lifters by 2025 will play a pivotal role in shaping the future of manufacturing and logistics.

Key Features to Consider When Selecting Magnetic Lifters for Industrial Use

When selecting magnetic lifters for industrial applications in 2025, there are several key features to consider that align with the latest advancements in the field. One of the primary considerations is the use of rare earth magnets, which are essential for enhancing lifting capabilities due to their superior strength-to-weight ratio. Recent government initiatives in India, including a ₹7,280 crore scheme to boost the production of rare earth permanent magnets, signify a growing emphasis on domestic manufacturing. This increase in availability and production can lead to more reliable and cost-effective magnetic lifters for industrial use.

Another important aspect is the efficiency of the magnetic lifter in various environments. As the industry evolves, companies are modeling and optimizing their processes, such as the removal of contaminants through innovative materials. For example, studies on magnetic chitosan composites have opened new avenues for efficiency in industrial applications, showcasing the integration of advanced materials to enhance performance.

Tips: When choosing a magnetic lifter, assess the load capacity and lifting height, as these specifications directly impact productivity. Additionally, consider the environmental conditions—such as exposure to moisture or heat—since these factors can affect the performance of the magnetic lifter.

Comparative Analysis: Manual vs. Automated Magnetic Lifters in 2025

In 2025, the industrial landscape is evolving with the integration of advanced technologies, thereby transforming the operational efficiency of magnetic lifters. A key aspect of this transformation is the comparative analysis between manual and automated magnetic lifters. Manual magnetic lifters still hold value in specific industries due to their reliability and simplicity. They offer a degree of flexibility that automated options may not provide, allowing operators to control lifting processes directly. However, this hands-on approach can sometimes lead to increased labor costs and potential safety risks, especially in high-volume operations.

On the other hand, automated magnetic lifters are rapidly gaining traction for their ability to enhance productivity and precision. These devices minimize the risk of human error and reduce the physical strain on workers, making them a safer alternative in environments requiring repetitive heavy lifting. Automation also allows for the integration of smart technologies, enabling real-time monitoring and adjustments to lifting processes. As industries strive to optimize their operations, the choice between manual and automated magnetic lifters will significantly depend on specific needs related to efficiency, safety, and investment in technology.

The Ultimate Guide to Magnetic Lifters in 2025 for Industrial Applications

| Parameter |

Manual Magnetic Lifters |

Automated Magnetic Lifters |

| Load Capacity |

Up to 1000 kg |

Up to 2000 kg |

| Ease of Use |

Requires manual operation and adjustment |

Automated with minimal operator involvement |

| Safety Features |

Basic safety switch |

Advanced sensors and emergency stop |

| Cost |

Lower initial investment |

Higher upfront cost but lower operational cost |

| Maintenance |

Regular manual checks required |

Automated diagnostics available |

| Versatility |

Good for various applications |

Highly adaptable for different settings |

| Training Requirement |

Basic operator training |

Specialized training needed |

Safety Standards and Regulations Governing Magnetic Lifters in 2025

In 2025, safety standards and regulations governing magnetic lifters have evolved significantly, reflecting an ongoing commitment to workplace safety and efficiency in industrial applications. The International Organization for Standardization (ISO) has updated its guidelines, and ISO 12895:2025 now includes specific requirements for magnetic lifters, emphasizing the necessity of rigorous testing and certification processes. This revision aims to mitigate risks associated with lifting heavy loads and ensure that all magnetic lifting devices comply with the latest safety protocols.

According to a recent report by the Occupational Safety and Health Administration (OSHA), incidents involving magnetic lifters have decreased by approximately 20% since the enforcement of updated regulations and standards, highlighting the effectiveness of these advancements. Additionally, the report points out that industrial facilities implementing these safety measures have reported substantial improvements in operational efficiency, with a noted increase of 15% in productivity. Companies are also encouraged to perform regular inspections and maintenance of magnetic lifters, as these practices further enhance safety and compliance with established guidelines, ultimately contributing to a safer working environment.

Future Trends: The Role of Smart Technology in Magnetic Lifting Solutions

As we move into 2025, the integration of smart technology into magnetic lifting solutions is set to redefine industrial applications. According to the International Federation of Robotics, the market for smart industrial equipment is projected to reach $500 billion by 2025, with a significant portion attributed to advancements in lifting technologies. Smart magnetic lifters now incorporate IoT capabilities, enabling real-time monitoring and data collection, which enhances operational efficiency and safety protocols. This technology allows operators to remotely track load weights, environmental conditions, and maintenance needs, ultimately reducing downtime and operational risks.

Furthermore, the trend towards automation in manufacturing necessitates the adoption of intelligent lifting solutions. A recent study by MarketsandMarkets indicates that the smart lifting equipment market is expected to grow at a CAGR of 12% from 2020 to 2025. This growth is driven by the demand for precision and the need for reduced labor costs. Magnetic lifters equipped with AI algorithms can optimize load balancing and lifting techniques, adapting to various materials and configurations in real time. This not only increases productivity but also enhances worker safety, as many hazardous lifting scenarios can be mitigated through automation and smart monitoring systems.